DAP Wall & Cavity Foam

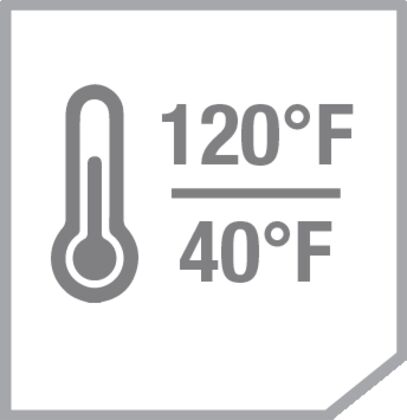

DAP Wall & Cavity Foam with Widespray Applicator is a portable, self-contained one-component polyurethane foam dispensing kit. Effectively air seal and insulate homes and buildings while enhancing R-Value, and providing Class A fire resistance. The patent-pending technology offers broadcast spray solution similar to two-component systems, but in a less complicated, easier to use one-component solution that can be applied in a wide temperature range 40°F – 120°F. Great for repairs, renovations and new installations. Use insulation spray foam kit to fill and seal interior areas like stud wall cavities, rim joists and basements. Also works for attic insulation and crawlspace insulation. Not to be used for direct overhead spraying applications.

Key Features

-

Wide Temperature Range

Wide Temperature Range -

Class A Fire Resistant

Class A Fire Resistant -

Saves Energy

Saves Energy

HOW TO USE

DETAILS + SPECIFICATIONS

- Details

-

Specifications

SKU Code Unit Size Color Dimensions (in.) Weight Case Pack Cases/Pallet 7565000351 00351 10.5 LB CREAM 9.81x7.81x14.94 17.06 lbs. 1 65 7565000352 00352 20 LB CREAM 12.06x10.06x17.44 28.41 lbs. 1 36 7565000353 00353 35 LB CREAM 12.5x12.5x18.81 43.05 lbs. 1 28

RESOURCES + FAQs

- Technical Data

-

FAQs

What should I do to prepare to spray?

Read all directions and cautions before use. Detailed instructions are provided inside the kit. Always wear gloves, eye protection and work gloves. Use drop cloths.

What surfaces will foam stick to?

Will adhere to wood, masonry, metals, and drywall.

How can I get optimal spray performance from my DAP Wall & Cavity kit?

For the best broadcast spray foam performance, temperature and mixing the foam inside the canister are key. Ensure the product is conditioned to 70F-85F at least 24hrs prior to use. The surface and ambient temperature of the project location should be 40F – 120F and relative humidity should be 40% or higher. The canister must also be shaken vigorously back and forth (side to side) for at least 30 seconds prior to use. See detailed instruction sheet included with product purchase for attaching hose and valve preparation.

What are some best practices for the Widespray applicator usage?

Ensure the applicator is in the OFF position and the nozzle is oriented horizontally prior to usage. Always test spray on scrap board or in a trash bin before use. It is best to hold spray nozzle 10-15” from material surface. The applicator is very responsive. Slowly push trigger forward to increase the flow. To switch between horizontal and vertical spraying, simply rotate hand so nozzle shifts from a horizontal to a vertical position. Do not re-position the tip, that will result in poor spray performance.

How much foam should I spray?

Rapidly and continuously spray no more than a ½” layer of wet foam. Allow 15+ minutes to allow for the initial moisture cure. Do not overfill/overspray the first layer. Note: for air sealing and thermal insulation purposes, one layer is sufficient (example: rim joists). If doing a full cavity fill for maximum R-value, two-layer application is required (example: wall cavity, attic, etc). For second layer applications, please see details instruction sheet included with product purchase. Important: Kit is not to be used for direct overhead spraying.

How much expansion should I expect?

When applied according to directions, it will expand 2.5 to 3 times. For example, a ½” layer of wet foam will expand to approximately 1.25” to 1.5” of cured foam.

How much coverage/yield will I get with DAP Wall & Cavity Foam?

A number on the lower right-hand corner of the package front will indicate theoretical* spray foam output. A board foot is defined as 12” x 12” square by 1” thick. The 10.5 LB size will yield up to 97 board feet, the 20 LB size will yield up to 185 board feet and the 35 LB size will yield up to 323 board feet. * Theoretical yield in board feet (12” x 12” x 1”). Actual output can be affected by several factors including temperature, humidity and blowing agent loss. The theoretical yield has become an industry standard for identifying certain sizes of spray foam kits. Theoretical yield calculations are performed in perfect laboratory conditions, without considering variations in application method and types.

What is the cure time?

Cure time is dependent upon temperature, humidity, and formulation. The foam surface is typically tack-free in 7-12 minutes, edges can be trimmed in 45 minutes, and is typically cured in 4 to 24 hours depending on foam thickness, temperature, and humidity. Cure time is increased in thicker applications, colder temperatures and/or low humidity. Once completely cured, excess foam can be trimmed if necessary.

Is the DAP Wall & Cavity spray foam insulation kit water resistant?

The cured foam will resist immediate water penetration. However, foam may absorb water that is in direct contact for extended periods of time.

Can I stop spraying and re-start later?

Yes, the DAP Wall & Cavity kit can be reused up to 30 days with proper storage techniques. To properly prepare for storage, turn the applicator to OFF position. Can use tape to secure for added layer of security. Remove tip and washer and clean-out any residual material thoroughly from nozzle with DAP Foam Cleaner or acetone. Do not empty hose. Close the valve on the top of the tank. Leave hose and applicator connected for reuse up to 30 days. Extra tips and washers are provided. Always store low-pressure polyurethane foam products upright in a dry, conditioned area. Do not expose to heat or store at temperatures above 122°F (49°C). The ideal storage temperature is 70–85°F (21–29°C), but not below 60°F (16°C) or above 90°F (32°C).

Is DAP Wall & Cavity Foam suitable for exterior / outside applications?

It is recommended for interior use only.

Why did the Wall & Cavity spray foam not cure properly after 24 hours?

Colder application temperatures (below 40°F require longer cure time), Humidity below 40% RH requires longer cure time. Wet foam application too thick (greater than ½” per layer).

Why is my spray pattern significantly narrowed when the canister is almost empty?

As the canister empties, a pressure drop occurs that reduces the spray pressure and force. If the dispense rate is slower or spray pattern is narrower than desired, then the trigger can be pushed forward to the next detent or fully open for faster flow and wider pattern.

What can I do if the relative humidity is lower than recommended?

To accelerate the cure time in dryer areas, mist surface with water, apply ½” layer of wet foam, and then immediately mist the entire foam surface. Wait until the surface is tack-free before applying additional foam layers or adding batt insulation for a “flash and batt” assembly.

USA - EN

USA - EN Canada - EN

Canada - EN